Moving Heavy Equipment & Machinery: A Complete Guide

The Political Disaster of the Inland Railway Project

April 8, 2019

The Different Types of HIAB Loader Cranes

August 30, 2019During the course of a build, moving heavy equipment from one location to another is an integral part of the process. It can be a daunting task and there are inherent risks associated with moving heavy loads. But, if done correctly, you’ll be able to move large machinery without any issues. Thus, it’s crucial to know how to move heavy equipment in a safe and efficient manner. Here is a complete guide for you to follow when moving heavy equipment and machinery.

Conduct a full risk assessment

The first step in moving heavy equipment is to conduct a full risk assessment. This will allow you to identify any potential dangers and mitigate them to a certain extent. As with any material handling procedure, accidents can happen, especially if we’re talking about heavy equipment. When carrying out a risk assessment, some factors worth considering are:

- Sharp edges on machinery that may cut or pierce the skin.

- Loose parts that have the potential to fall down while moving.

- Rotating mechanisms where garments can get caught or jammed.

- The weight load of the equipment to be moved.

If several control measures have been applied and there are still risks in terms of worker safety, then the use of personal protective equipment (PPE) should be implemented. A risk assessment will help identify what types of PPE are needed to safeguard workers from the hazards involved in moving heavy equipment and machinery.

Have a detailed plan of the moving process

Having an outline of the entire moving process will go a long way towards enhancing the productivity of the workers. This means planning where the equipment will be moved and which moving equipment to use. For example, you can prioritise moving the heaviest equipment first so you have more room to make adjustments later on. This reduces the amount of time moving the equipment from one location to another since there are less obstacles in the way. From there, you can decide which tools are needed to make the moving process much easier.

Use tools designed for moving heavy equipment

When it comes to material handling, there are certain tools that make the task less strenuous. Making use of these tools will help facilitate the moving and minimise the hazards associated with it. Here are some of the tools that should be in your arsenal:

- Machine skates

As you know, moving anything with wheels is much easier and machine skates make moving heavy equipment a breeze. Machine skates come in a rectangular platform that has wheels attached to them. The heavy equipment is placed on top of the platform which allows it to glide easily over floors. The added mobility will make a huge difference in terms of how fast you’ll move the machine from point A to point B.

Some machine skates use wheels that rotate 360 degrees which provides better control when moving heavy equipment. Be sure to check the capacity of the machine skates and see how much weight it can handle so it doesn’t impede its movement.

- Roller skids

Roller skids are an upgraded version of machine skates where it can be bolted onto heavy machinery for better stability. A toe jack or forklift is used to lift the heavy equipment and then the roller skids are slid underneath. Once the equipment is in place, the roller skids are affixed firmly to the machinery.

- Toe jacks

Toe jacks are an essential tool for any heavy material handling. These can come in quite handy if you don’t have a forklift at your disposal. You need toe jacks to lift and lower heavy equipment onto machine skates. The front of the toe jack is where the toe is located (a fork-like part of the tool) that slides beneath the heavy equipment. The hydraulic pump then lifts the toe to the required height, allowing you to slide in machine skates and roller skids before lowering it down.

These tools come in a number of different weight capacities that make them suitable for any material handling operation. If the equipment is too heavy, multiple toe jacks can be used to lift the machine from the floor.

- Hand trucks

Some machines aren’t huge, but are extremely heavy which makes it very difficult to move. In this case, hand trucks are the perfect solution. Hand trucks are two-wheeled hand carts that have a platform on end, and handles on the other end. You’ve probably seen hand trucks a supermarket where the employees use it to move boxes of goods.

But you may not know that there are different types of hand trucks. The main difference is the load capacity. There are machine hand trucks that are purposely built to handle tall, heavy equipment. Machine hand trucks are built more rigid than conventional hand trucks to accommodate the sheer weight of heavy equipment.

Transport services

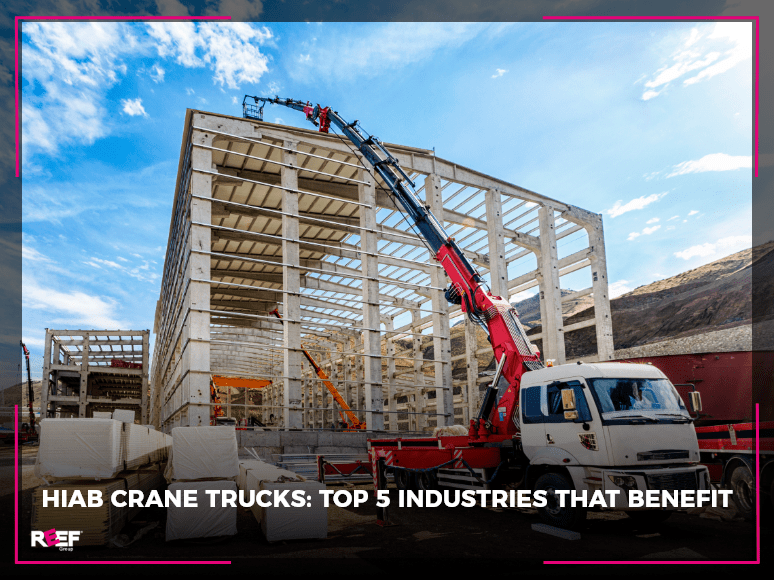

Some construction sites require moving massive machines where conventional moving tools aren’t enough to get the job done. If this is the case, then you should consider hiring a professional machinery transport service. Transport and freight companies use HIAB crane trucks, tilt tray slide trucks, and low loaders to move even the heaviest of machinery and transport them safely and efficiently.